Geotechnical and Materials

Recent research topics include geosynthetics, ground improvement, earth retaining structures, pile foundations, pipe-soil interaction, geomechanics, soil modification/stabilization using lime and fly ash, geographic information systems/site investigation, quality measurement of lime stabilized soil and HMA using nondestructive methods, recycled asphalt pavements, and pavement design.

Geotechnical Engineering Laboratories

The 1,300-square-foot Asphalt Laboratory in 1178 Learned Hallrepresents the first upgrade to our geotechnical labs. With the addition of this sophisticated Asphalt Lab, KU will be one of a few universities in the country able to conduct research that could change asphalt for use in the public and private sectors.

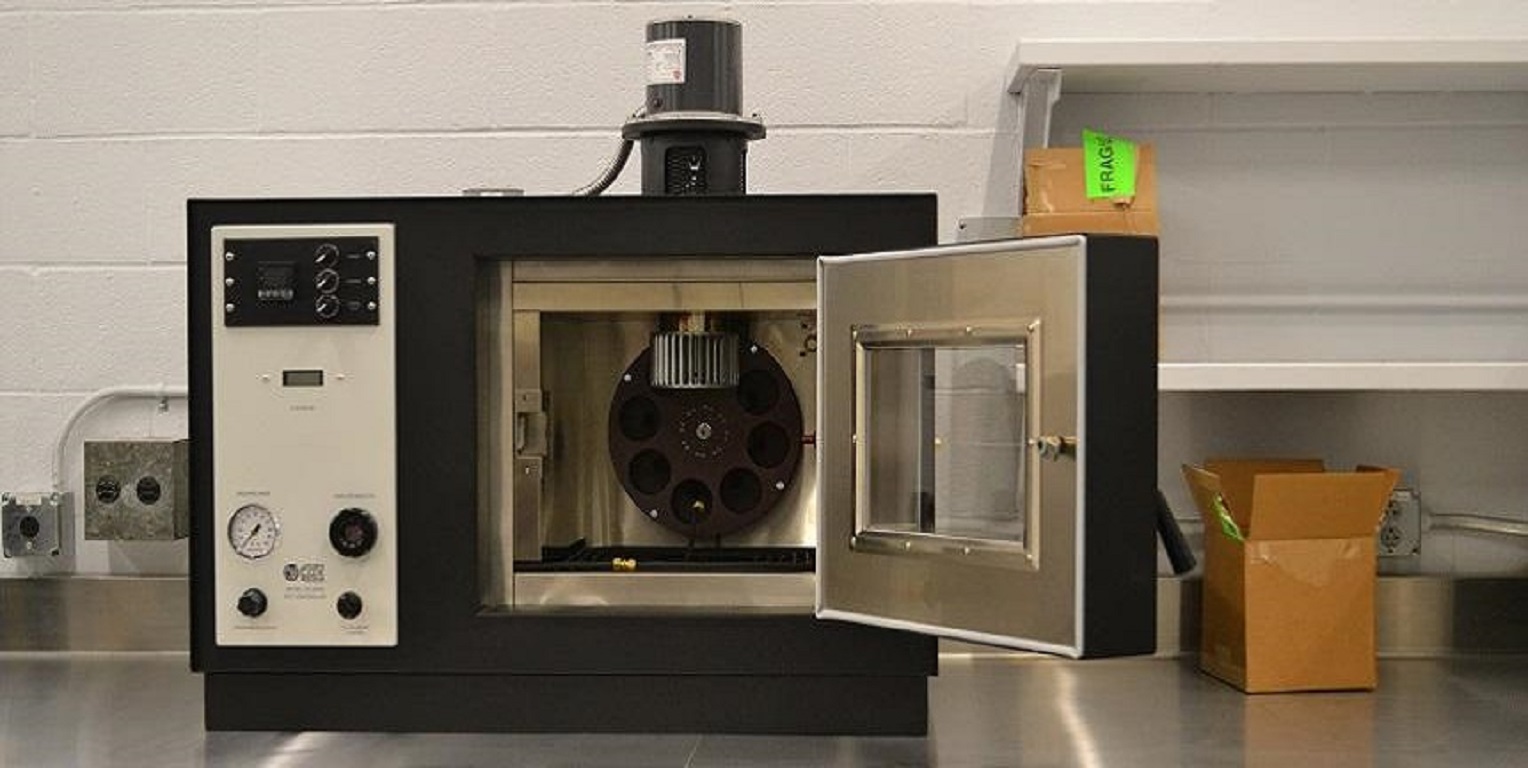

The new state-of-the-art equipment includes an ignition oven for asphalt binder, a rotational viscometer, a centrifuge and Abson extraction device for asphalt, a large oven, an asphalt pavement analyzer, a gyratory compactor, a light falling weight deflectometer, a dynamic cone penetrometer, a geo-gauge, a large-scale test box, a railway testing facility, a cyclic loading frame for asphalt overlay testing, and California kneading compactor. It will allow researchers to characterize asphalt in a very modern way, specific to a multitude of changing climate conditions. Dr. Masoud Darabi, who will be teaching the Transportation Materials class in the new lab, is planning research on how to develop an asphalt material that will be more resistant to cracking and that may potentially be able to heal itself

In addition to the latest technology in research, students will benefit from the state-of-the-art class equipment and features. The new lab space will allow students to become familiar with the equipment, provide room to perform and observe a variety of tests, enable them to work on the composites that are being used in the advanced materials industry, and gain experience that will open a number of new job opportunities.

The Concrete Laboratory is located in 1167 Learned Hall. The Laboratory is equipped to run standard tests on cement, aggregates, and concrete. The laboratory is operated as both a teaching and research facility. Equipment is available to test concrete aggregate for deleterious behavior, including alkali silica reactivity, and to measure aggregate properties as they affect mixture proportioning. Freeze-thaw equipment is available for running tests under both Procedures A and B of ASTM C666. A walk-in freezer is used for scaling tests. Concrete is cured under controlled temperature and humidity in the lab's curing room. Two hydraulic testing machines, with load capacities of 180 tons (400,000 lb), are used for concrete strength determination.

The Corrosion Testing Laboratory is in 1151 Learned and is equipped with an electrochemical impedance system, potentiostats, voltmeters, reference electrodes (Calomel and copper-copper sulfate), ion-specific electrodes, and heating tents for Southern Exposure and cracked beam tests. Southern Exposure and cracked beam specimens. Specimens are used for evaluating reinforcement and admixtures for corrosion resistance under alternating cycles of salt exposure and elevated temperature. A pore press provides the capability of extracting pore solution from hydrated cement paste, mortar, and concrete. The lab is also equipped with a salt-spray cabinet, a Taber abraser, and an ASTM G14 impact tester. The lab can evaluate epoxy coatings on reinforcing steel in accordance with ASTM A775 and A934 and evaluate the corrosion resistance of stainless steel reinforcement in accordance with ASTM A955.

The Environmentally Controlled Laboratory is located in 1153 Learned Hall. The lab has a temperature and humidity-controlled chamber with over 300 square feet of floor space to allow for testing of hundreds of concrete specimens for free shrinkage and scaling resistance. The lab is equipped with automated machines capable of exposing up to 60 specimens to freezing and thawing cycles. Three saturated lime-water tanks provide space for curing hundreds of specimens prior to testing.

The Geotechnical Engineering Laboratory is located in 1184 Learned Hall. The Laboratory has oedometers, Atterberg limit apparatus, specific gravity apparatus, sieves, shakers, and a vibrating stable, maximum and minimum density molds, Proctor compaction molds and hammers, large and standard direct shear devices, a triaxial shear device, large-scale and small geotechnical boxes, a geosynthetic creep testing device, a field pile loading system, earth pressure cells, piezometers, and static and dynamic data acquisition systems, etc.

The Large-Scale Geotechnical Testing Laboratory is located on West Campus. The Laboratory consists of a large-scale geotechnical testing box, a large-scale loading frame for railway testing, and several material bins for the storage of soil, aggregate, and ballast. The testing facility is also equipped with a 55-kip actuator, a Bobcat front loader, a forklift, two vibratory plate compactors, a jump jack compactor, in-situ testing devices (vane shear test device, dynamic cone penetrometer, and lightweight falling deflectometer), and instrumentation sensors (earth pressure cells, displacement transducers, and moisture sensors) and a data acquisition system. This testing facility has been used for geotechnical teaching and research, including but not limited to geosynthetic-reinforced unpaved and paved roads, railways, buried pipes, retaining walls, and shallow foundations.

The Mechanics of Materials Teaching Laboratory is located in room 1421 of LEEP2, the new engineering teaching and research facility that opened in 2015. The facility is a teaching space used for conducting experimental laboratories associated with undergraduate courses, including CE 310, Strength of Materials, and ME 307, Engineering Materials Laboratory.

The Mechanics of Materials Teaching Laboratory is equipped with six tabletop testing frames suited for hand-driven mechanical testing of metallic and polymeric specimens. Students can use the test frames to conduct tensile, flexural, shear, and compressive tests using a variety of available fixtures. The laboratory also houses a closed-loop screw-type test frame for testing larger specimens, a pair of tabletop hardness testers, high-resolution microscopes for examining failure surfaces, and grinding equipment for preparing specimens for testing.